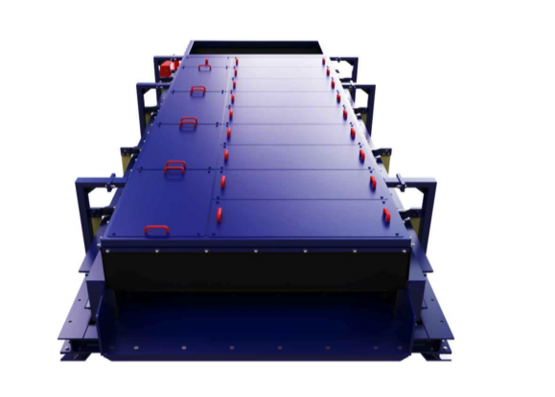

Linear Horizontal Screener

What Is A Linear Horizontal Screener ?

Linear Horizontal Vibrating Screeners are one of the most commonly used separators as a result of their versatility and adaptability despite there non-conventional design.

In simple terms, horizontal screens focus on providing G-Force to vibrate and excite the material or feed down the length of the screen,

Operating at 0 degrees, differentiating them from their sister inclined screens, they can be adjusted to a maximum of around 10 degrees in either direction.

Usually made up of a dual or three shaft design located within the screen box’s centre of gravity, with timing gears and counterweight designs to create either an oval or linear motion.

Sometimes offering linear motion via an out-of-balance motor or excited gears, within which eccentric weights are mounted on either end of the shaft located onto of the epicentre of the screens gravity to provide vibration motion.

What Are The Benefits Of Using Linear Horizontal Screeners ?

High Levels Of Efficiency

The material is held on the screen for longer than other methods of screening, due to a slower rate of travel to the end of screen, this allowing more proper sized materials to fall through the mesh apertures.

Portable & Space-Saving

Often used in portable plants due to their easy transportation and low profile, making them a great option for mobile environments and plants that require regular movement of machinery.

High Levels Of Control

The stroke of horizontal screens can be adjusted between a large range, generally operating with a stroke of between 16-18mm and with a 750rpm speed. As the strokes and gradients can be easily modified the screening media can vary in speed allowing for control over difficult to screen materials.

Less Maintenance Costs