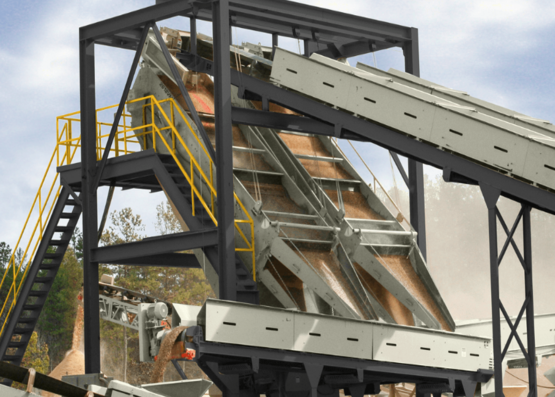

Ultra High Frequency Screener

Ultra High Frequency Screeners

Ultra high frequency screeners are one of the most important machines for the mineral processing industry due to their ability to separate feeds containing solid and crushed ores down to less than 200μm in size.

The frequency is controlled by an electromagnetic vibrator commonly mounted above the screening directly connected to the screening deck.

Usually operating at an inclined angle, between 0 -25 degrees, high frequency screeners are differentiated based upon their frequency range from 1500 to 9000rpm.

Similar to inclined screeners, the vibration creates a lift on the screen media causing stratification and the inclination causes the product to travel down the deck.

The Ultra High Frequency Screeners are used for the finest of materials to agitate and excite the particles for increased stratification for the smallest of screen apertures.

What Are The Benefits of Ultra High Screeners ?

Extremely High Efficiency

The high frequency of vibrations breaks down the surface tension between particles and the high level of RPM’s contributes to Incan increased stratification of the screen media increasing the separation rate.

High Precision And High Yields

With a huge degree of control over both the angle of inclination and RPM’s the operator can set the parameters to perfectly suit the application and screen media ensuring that extremely small apertures excrete all of the undersized product and undersized product is not discharged as oversized. Perfect for applications where precision is key and the highest of yields are required.