Here you can download Brochures and datasheets to further inform you about this machine’s technology and specifications.

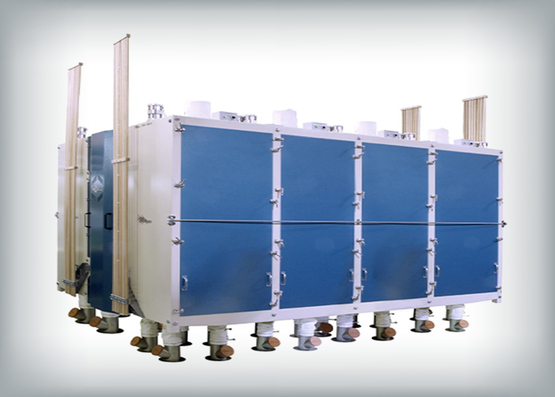

Sieve housings are constructed of kiln-dried maple and birch plywood with painted exterior finish (as shown) or finished with moisture resistant lacquer. Dust-tight doors and crevice free joints assure sanitary operation. Interiors are bonded with either white plastic laminate as standard to meet sanitary requirements, or stainless steel for increased demand.

Press Tops

Press tops maintain a securely compressed sieve stack. The HS Sifter is available with either the manual rack-and-pinion sieve compression system, or Great Western’s innovative pneumatic sieve compression system.

HS Drive

The Great Western HS drive mechanism provides uncomplicated adjustment of weights. This allows for the wide range of speed-throw combinations required for optimum operation to meet your product separations.

As the sifter starts, the radial centrifugal force is used to lift the two weight compartments up and together through accurately machined cams while compressing a spring. This controlled energy assures a smooth gyratory motion.

The drive, motor, and counterweight assembly solidly connect to the two boxes. This lightweight, well proven design combines the three elements into one structure capable of withstanding the dynamic stresses required for years of continuous operation.

Bottom Distributors and Outlets

The bottom distributor routes the separated product streams to the outlets. The design can provide up to eight separate uninterrupted discharges.

APPLICATION

SCREEN MATERIAL

Is your machine listed on our page with out of date information or do you need to make contact regarding a recent update to your machine?

DESIGNED, PROGRAMMED AND HOSTED BY STAUNTON ROOK MARKETING